How a Direct Online Starter Works

A Direct online starter is a method of starting small electric motors, typically those rated 4kW and below.

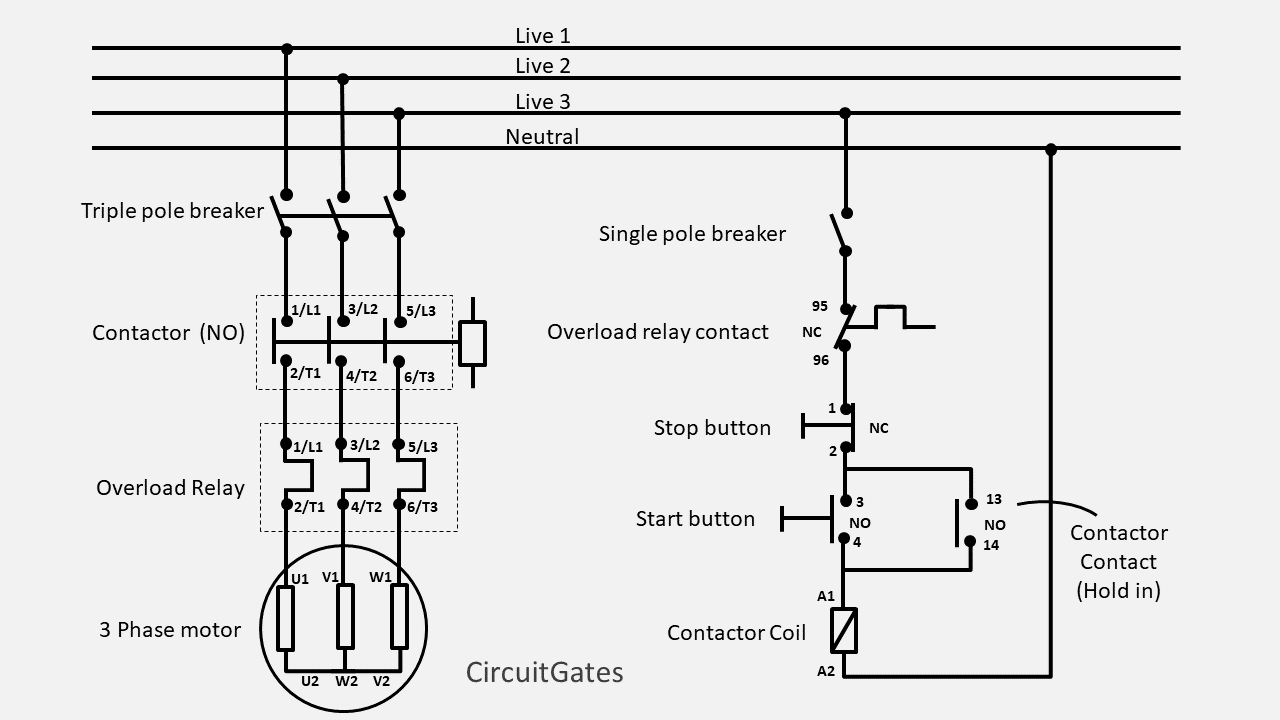

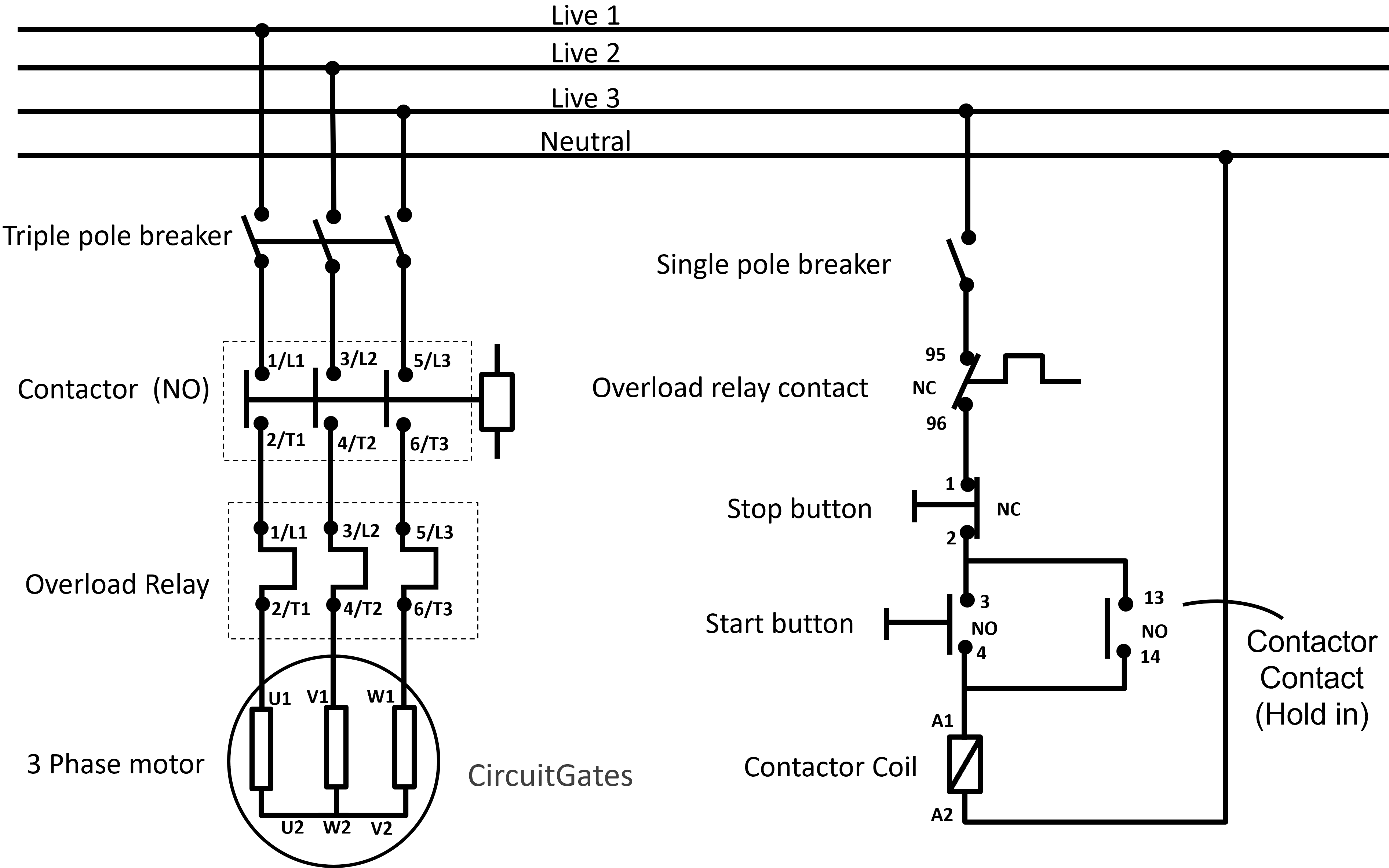

It consists of two circuits: the power circuit and the control circuit. The power circuit provides power to the electric motor, and the control circuit, controls the operation of the electric motor.

Power and Control Circuits

- L - Live

- NO - Normally open

- NC - Normally closed

Key

Components of a Direct Online Starter

A Direct Online Starter Consists of:

1. Start Button - A normally open contact button that is pressed to run the electric motor .

2. Stop Button - A normally closed contact button that is pressed to stop the electric motor.

3. Circuit Breakers - are either manually operated to switch off the circuit for maintenance or they automatically trip, breaking the circuit in the event of a fault.

4. Overload Relay - An overload relay breaks or switches off the circuit in the event of overload that causes overheating of the electric motor windings.

Overload is a condition in which the current flowing in a circuit exceeds the amount required, leading to overheating of the electric motor windings that results in the burning of the electric motor. Overloads usually do not cause tripping of circuit breakers, therefore there is a need for an overload relay.

5. Contactor - A contactor is a device that when current flows through its coil, closes the contacts of the power circuit for power to reach the electric motor and vice versa.

6. Electric Motor - An electric motor is a device that converts electrical energy into mechanical energy.

How a Direct Online Starter Works

On a direct online starter, assuming the circuit breakers are in the ON position, when the start button is pressed, current is allowed to flow through the contactor coil.

The flow of current through the contactor coil causes the contactor power contacts to close, resulting in power reaching the electric motor and the electric motor begins to run.

The 13/14 contactor contact that is in parallel with the start button serves as a hold-in contact. The 13/14 contact is a normally open contact; it is put in the closed position when the contactor coil is energized.

Since the start button is a normally open contact, soon after pressing it, it returns to its normally open position. Current will then continue to flow to the energized contactor coil through the 13/14 contact.

To stop the electric motor, the stop button is pressed; this cuts the supply of current to the contactor coil, causing the contactor power contacts to open and the electric motor to stop running.

Why is a Direct Online Starter only used for Small Electric Motors?

The starter starts an electric motor by directly applying full line voltage to the electric motor terminals, and this poses a significant risk to larger electric motors. Since large electric motors are typically designed to run in delta configuration, directly connecting them to full line voltage in delta would cause excessive current flow during startup, potentially leading to destruction of the electric motor. Therefore, other starting methods like the star-delta starter are necessary, where the electric motor is started in star configuration and then switched to delta to run.Advantages and Disadvantages of a Direct Online Starter

Advantages

The circuit is simple, easy to understand ,and to install.

It needs few components, therefore it is less expensive.

The circuit is easy to troubleshoot.

It offers protection to electric motors by automatically switching off the electric motor in the event of a fault.

It provides a safe environment to the people working with the electric motor.

Disadvantages

Starting current is very high.

It is limited in use, only applicable to small electric motors.