How a Star-Delta Starter Works

A Star-delta starter is a method of starting larger induction electric motors, typically those rated 4kW and above.

In star-delta starting, the electric motor first runs in star and is then switched to delta after reaching 80% of its full load speed.

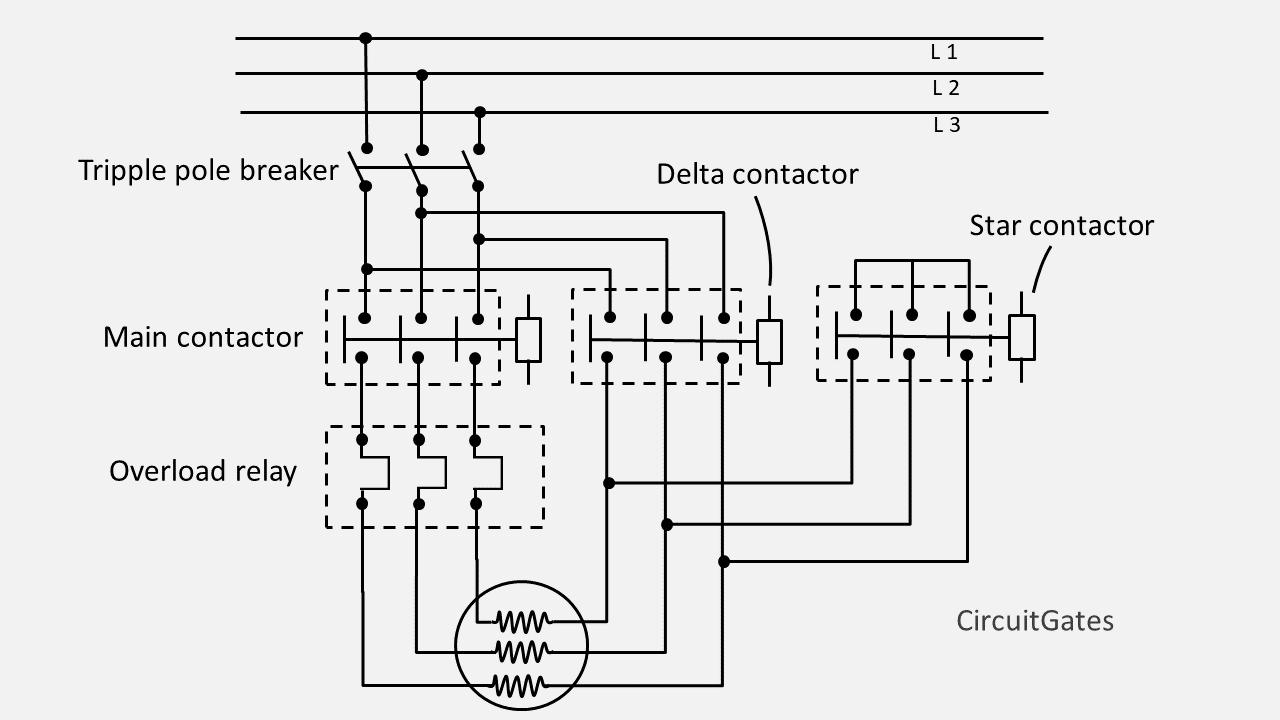

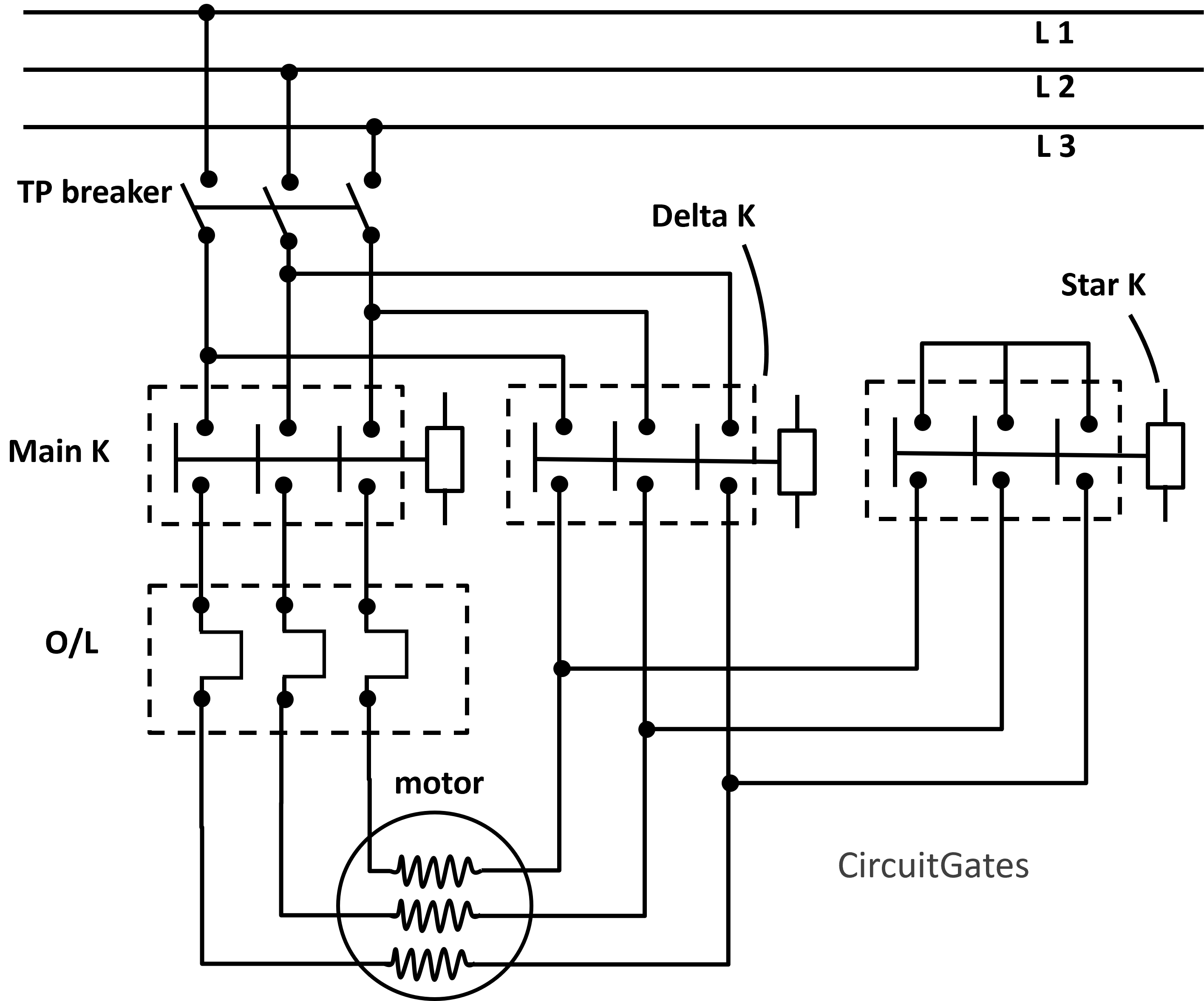

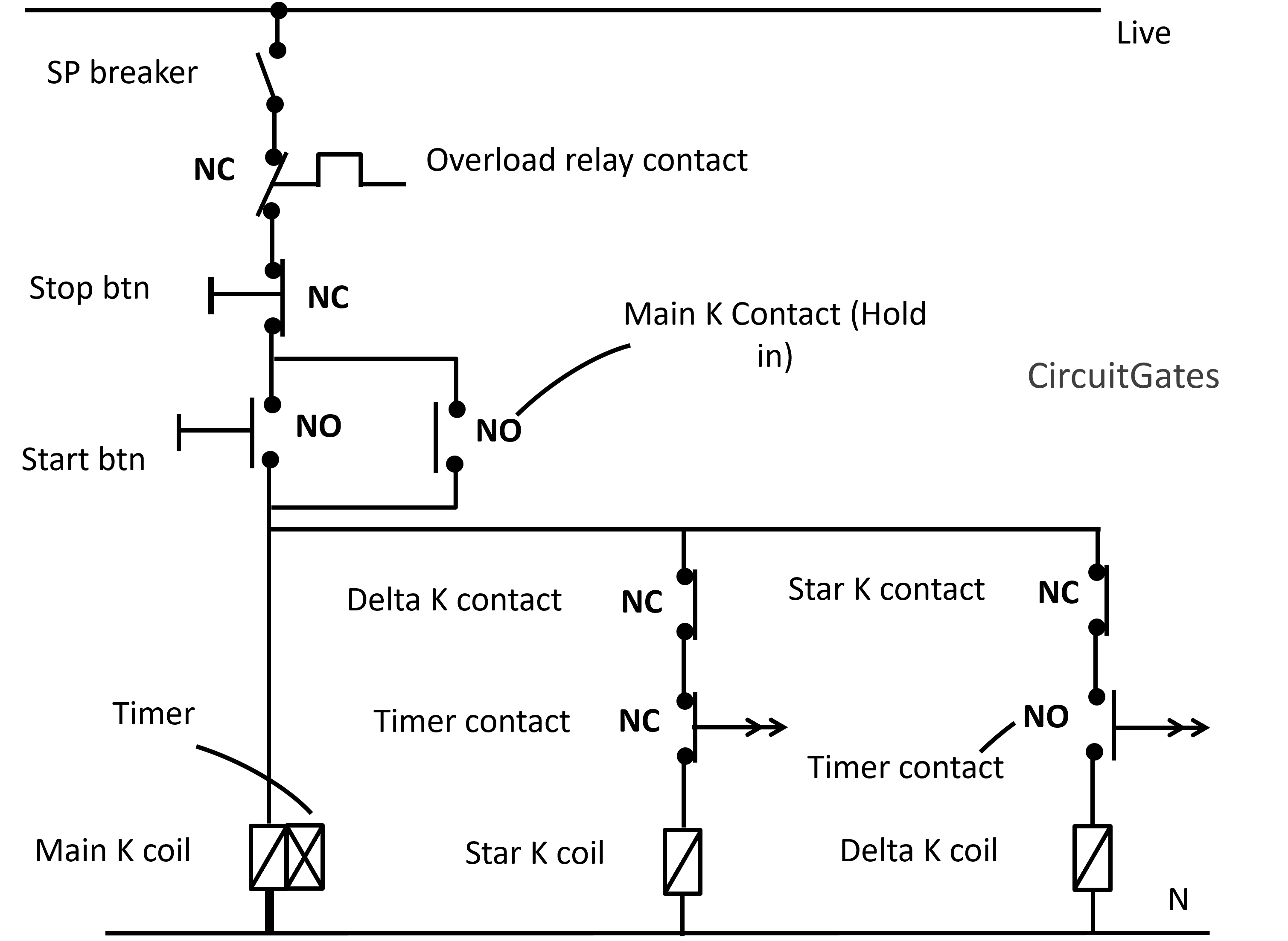

The star-delta starter consists of two circuits: the power circuit and control circuit. The power circuit provides power to the electric motor and the control circuit, controls the operation of the electric motor.

Power Circuit

Control Circuit

- TP Breaker - Tripple pole breaker

- SP Breaker - Single pole breaker

- K - Contactor

- btn - Button

- NC - Normally closed

- N - Neutral

- O/L - Overload relay

- NO - Normally open

Key

Components of a Star-Delta Starter

A Star-Delta Starter Consists of:

1. Start Button - A start button is a normally open contact button that is pressed to run the electric motor.

2. Stop Button - A stop button is a normally closed contact button that is pressed to stop the electric motor.

3. Circuit Breakers - Circuit breakers are either manually operated to switch off the circuit for maintenance or they automatically trip, breaking the circuit in event of a fault.

4. Overload Relay - An overload relay breaks or switches off the circuit in event of overload that causes overheating of the electric motor windings.

Overload is a condition in which the current flowing in a circuit exceeds the amount required, leading to overheating of the electric motor windings which results in the burning of the electric motor. Overloads usually do not cause tripping of circuit breakers, therefore there is a need of an overload relay.

5. Contactors (Main, Delta and Star) - Contactors are devices that when current flows through their coils, close the power circuit contacts, allowing power to reach the electric motor and vice versa.

6. Timer - A timer enables the electric motor to switch from star to delta.

7. Electric Motor - An electric motor is a device that converts electrical energy into mechanical energy.

How a Star-Delta Starter Works

On a star-delta starter, assuming the circuit breakers are in the ON position, when the start button is pressed, current is allowed to flow through the main contactor and star contactor coils.

When current flows through the two coils, the power contacts of the main and star contactors are pulled to the closed position and power reaches the electric motor and the motor begins to run in star configuration.

After a preset time has reached, the timer opens the star contact and closes the delta contact.

This stops current from flowing through the star contactor coil and enables current to flow through the delta contactor coil, thus opening the star contactor power contacts and closing the delta contactor power contacts and the electric motor is switched to delta.

The main contactor contact labeled "hold in" that is in parallel with the start button serves as a hold-in contact. This contact is a normally open contact; it is put in the closed position when the main contactor coil is energized.

Since the start button is a normally open contact, soon after pressing it, it returns to its normally open position, current will then continue to flow to the energized contactor coils through the hold-in contact.

To stop the electric motor, the stop button is pressed; this stops current from flowing through energized contactor coils, causing contactor power contacts to open and the electric motor to stop running.

Why Large Electric Motors are Connected to Star-Delta Starter?

Let's look at star and delta configurations. A star configuration has higher impedance than a delta configuration.

When an electric motor is running, a back electromotive force (e.m.f) is produced in its windings, opposing current flow.

However, when starting, there's no back e.m.f, so the current depends on the configuration used.

If a large electric motor is started in a delta configuration (which has low impedance), too much current will flow, potentially damaging the motor. Hence, starting in a star configuration is necessary.

On the other hand, running a large electric motor in a star configuration (which has high impedance) would reduce the current. Therefore, a delta configuration is needed for running.

This is why large electric motors are started in star and then switched to delta to run.

Advantages and Disadvantages of a Star-Delta Starter

Advantages

The starting current of larger electric motors is greatly reduced.

If properly installed, the response time to faults and operations is very short.

It offers protection to electric motors by automatically switching off the electric motor in the event of a fault.

It provides a safe environment to the people working with the electric motor.

Disadvantages

It is a complex circuit, difficult to understand, and to install.

It needs more components than other starting methods, making it a more expensive method.

Difficult to trace a fault.