What is SCADA and How SCADA Works

SCADA - Supervisory Control And Data Acquisition is a system used to control processes in industrial sites and other various areas.

A process involves several machines working together to transform raw materials or components into finished goods or products.

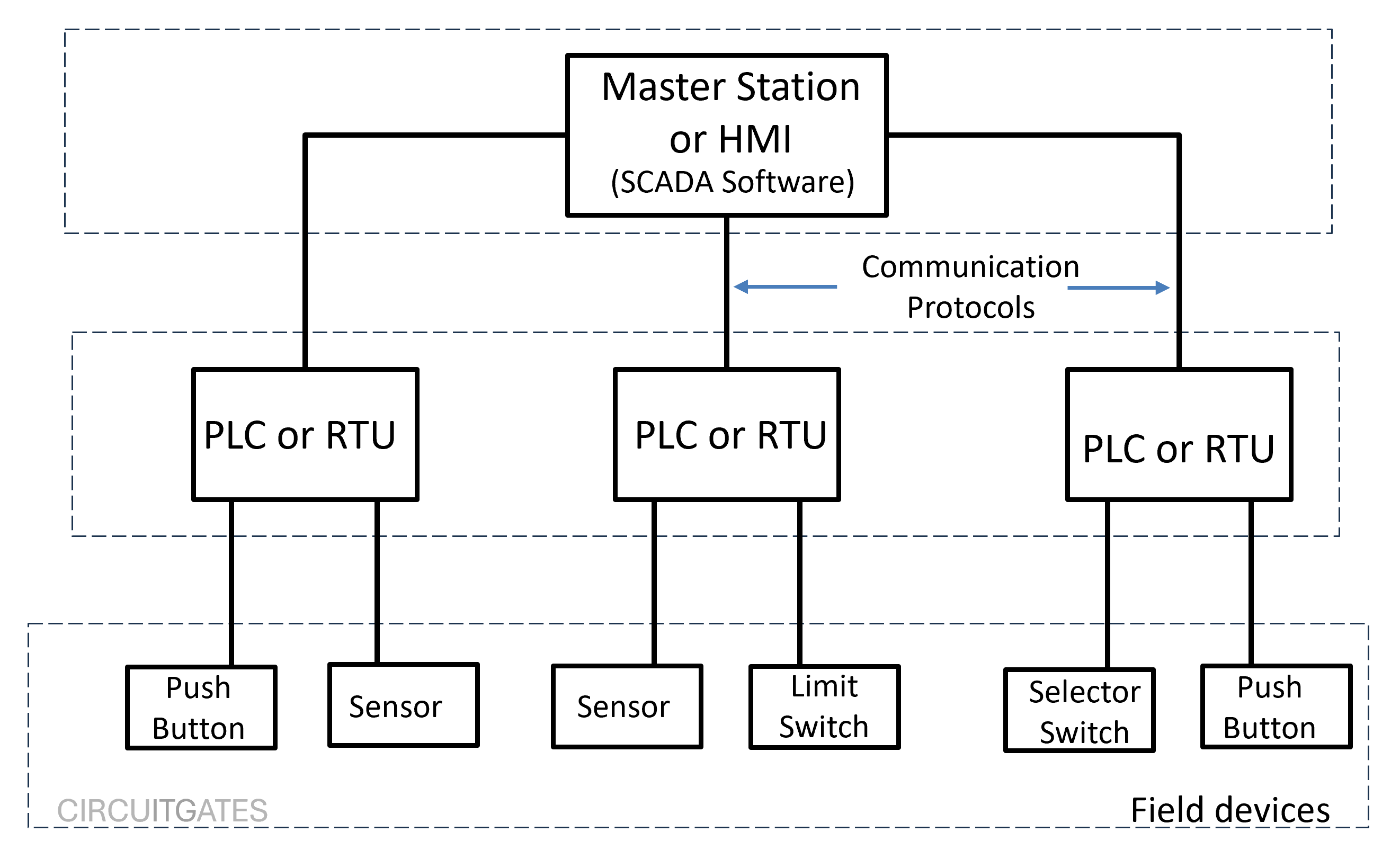

The machinery of a process can be scattered over long distances, cover a wide area, or simply be large in number. In a process, each piece of machinery can have its own PLC controlling it.

When controlling a process using SCADA, all the PLCs send the data they receive from field devices to one central place, usually called the HMI.

These PLCs also receive control commands from the HMI based on the data they report.

At a basic level, the HMI is essentially one computer with SCADA software installed in it that processes the data from the PLCs and sends control commands back to the PLCs.

The HMI also has a screen that displays the critical conditions from all the process machinery and provides a platform for the operator to issue controls.

The use of SCADA allows the operator to monitor all aspects of the process, issue controls to the machinery, and precisely determine where a fault has occurred - all from one location.

The SCADA control process involves several stages: the stage of data collection from machinery being controlled, the stage of processing and understanding the collected data, and the stage of issuing control to the machinery.

The main purpose of SCADA is to reduce downtime and maximize production.

If you understand PLCs very well, SCADA involves PLCs and an additional control layer above the PLCs in its control of industrial processes.

SCADA is not a single software; it involves several SCADA hardware components and software working together to form what we call a SCADA system.

SCADA Hardware Components

These are tangible parts of the SCADA system. We have several SCADA hardware components that are involved, starting from data collection, processing, and up to control. These components include field devices, PLCs, RTUs, and HMIs.

Field Devices

Field devices are the actual physical components of the SCADA system that directly interact with the process machinery. These devices are grouped into input field devices and output field devices.

Input Devices

Input devices are field devices that collect data about the machinery a SCADA system is controlling. Examples of input devices include limit switches, proximity switches, and push buttons.

Nowadays, in SCADA-controlled machinery, you rarely find simple input devices like start and stop buttons; sensors such as limit switches, proximity switches, liquid level switches, and daylight switches are used much more often.

The data collected by the input devices is sent to the PLCs or RTUs. The data is transmitted as either a digital signal or an analogue signal, which we cover in the following paragraphs.

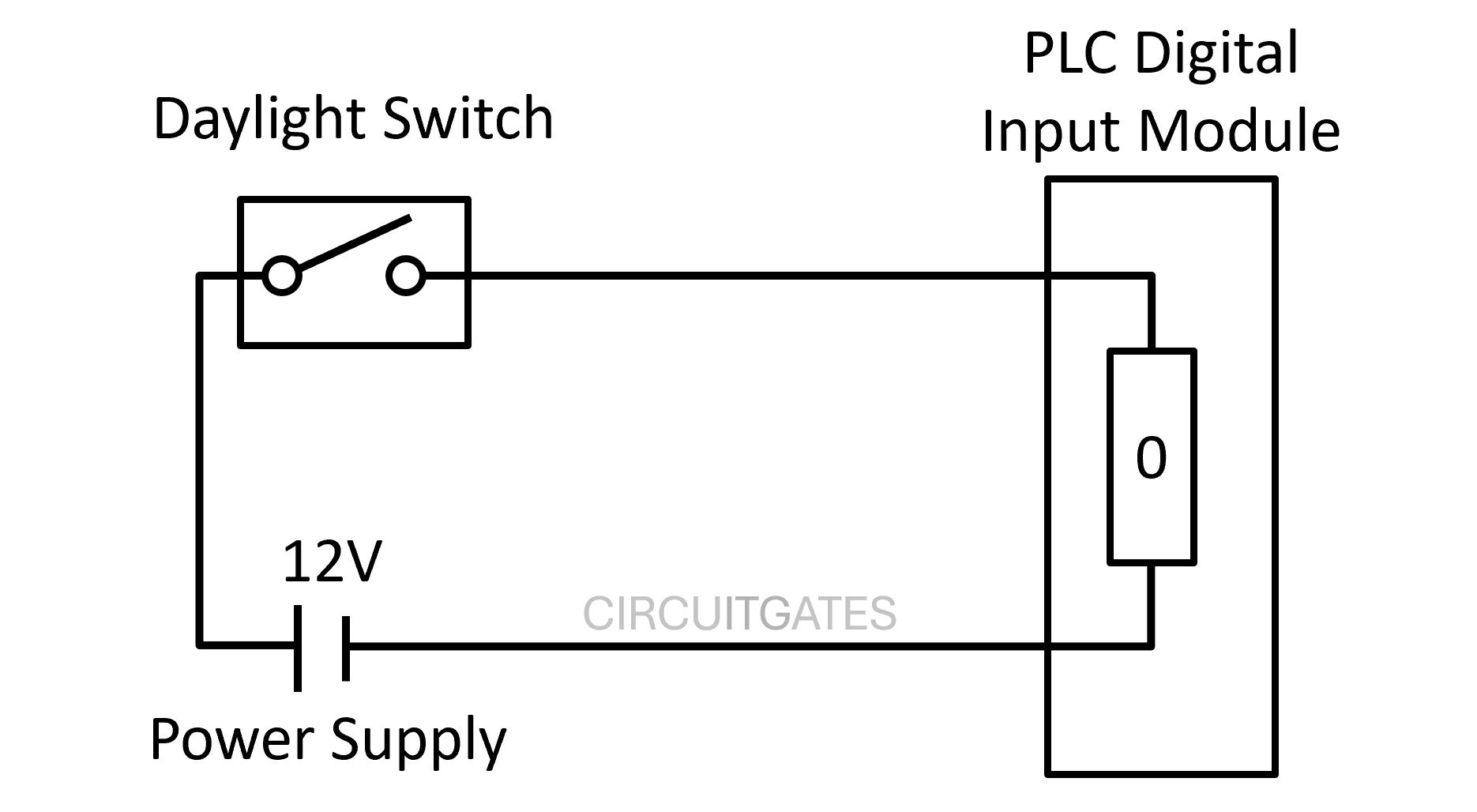

Here is an example of data collection: a daylight switch used to turn lights ON when it senses darkness.

When darkness occurs, the daylight switch senses it and signals the PLC by allowing current to flow to the PLC's input. When current flows, the PLC recognizes that there is darkness, and in this way, data is collected.

Output Devices

These are the field devices that receive control commands for the process machinery from the PLCs or RTUs. Output field devices include relays, contactors, and indicator lamps.

The control command data received by output field devices from PLCs and RTUs is also in the form of eihter a digital signal or an analogue signal.

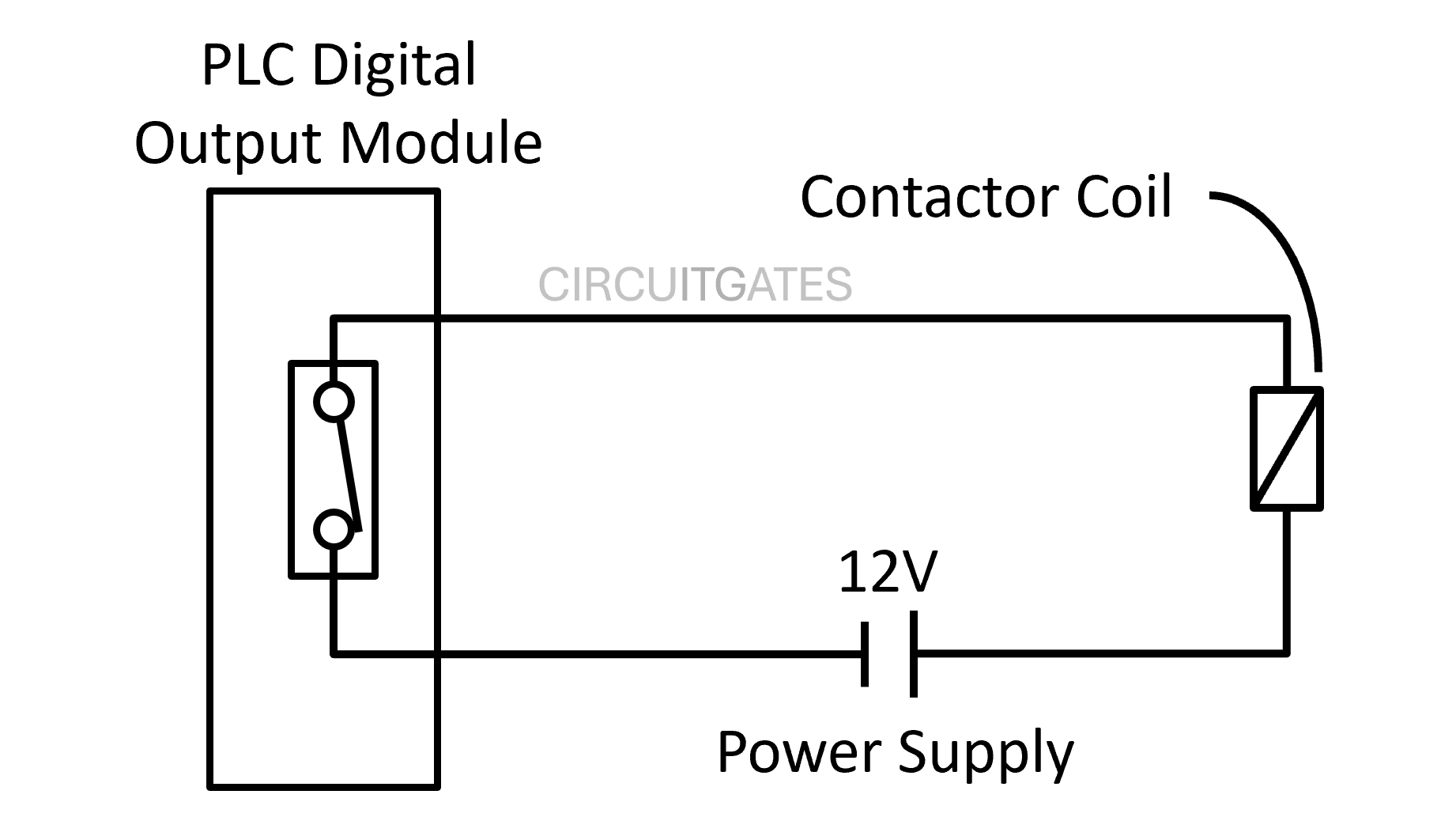

Example of a control command: a contactor used to start an electric motor.

For a PLC to send a run command to the electric motor through the contactor, it creates a flow of current through the contactor coil, energizing it, which causes its power contacts to close and allows power to reach the electric motor.

A digital signal is an individual signal that is either ON or OFF (1 or 0). In digital inputs and outputs, when current flows, the signal is 1, ON, or True. When no current is flowing, the signal is 0, OFF, or False.

An analogue signal is a continuous signal. The change in value within the continuous signal's range signifies a change in the physical parameter being monitored. An analogue signal can be transmitted using current (e.g., 4-20mA) or voltage.

Data Collecting Devices: PLCs and RTUs

These are devices between the HMI and the field devices. They are directly connected to the HMI and the field devices.

PLCs and RTUs typically consist of input modules, output modules, and a processor. The input modules are connected to the field devices and the HMI. They receive data from the field devices and control commands from the HMI.

Input modules connected to the HMI usually use communication protocols for connection or communication.

The output modules are connected to the output field devices. They send control signals from the PLCs and RTUs to the output field devices.

The processor is the part that reads the input signals from the input devices and HMI, and then determines what signal to send to the output field devices.

The PLCs and RTUs have internal memory, which contains input image tables and output image tables that store the current state of their inputs and outputs.

Input image tables are used to store data from field devices and the HMI. A specific input value within the PLC or RTU's input image table is called a register.

In SCADA, the HMI regularly scans the data in the registers of the input image tables of the PLC and RTU. After scanning and processing the data, the HMI sends control data, which is received by the PLC or RTU as a new input.

The processor of the PLC or RTU regularly scans the data in the input image tables and then updates the output image tables of the PLC or RTU. Output image tables are used to store data which is sent to the output field devices.

PLCs

Programmable Logic Controllers are devices designed for use in areas where fast processing is required, the process machinery covers a smaller area, and high-speed data transfer is needed.

PLCs use programming languages such as ladder logic and structured text to write the control programs that the PLC processor follows when executing tasks.

PLCs are designed in such a way that they can be used without SCADA in small processes.

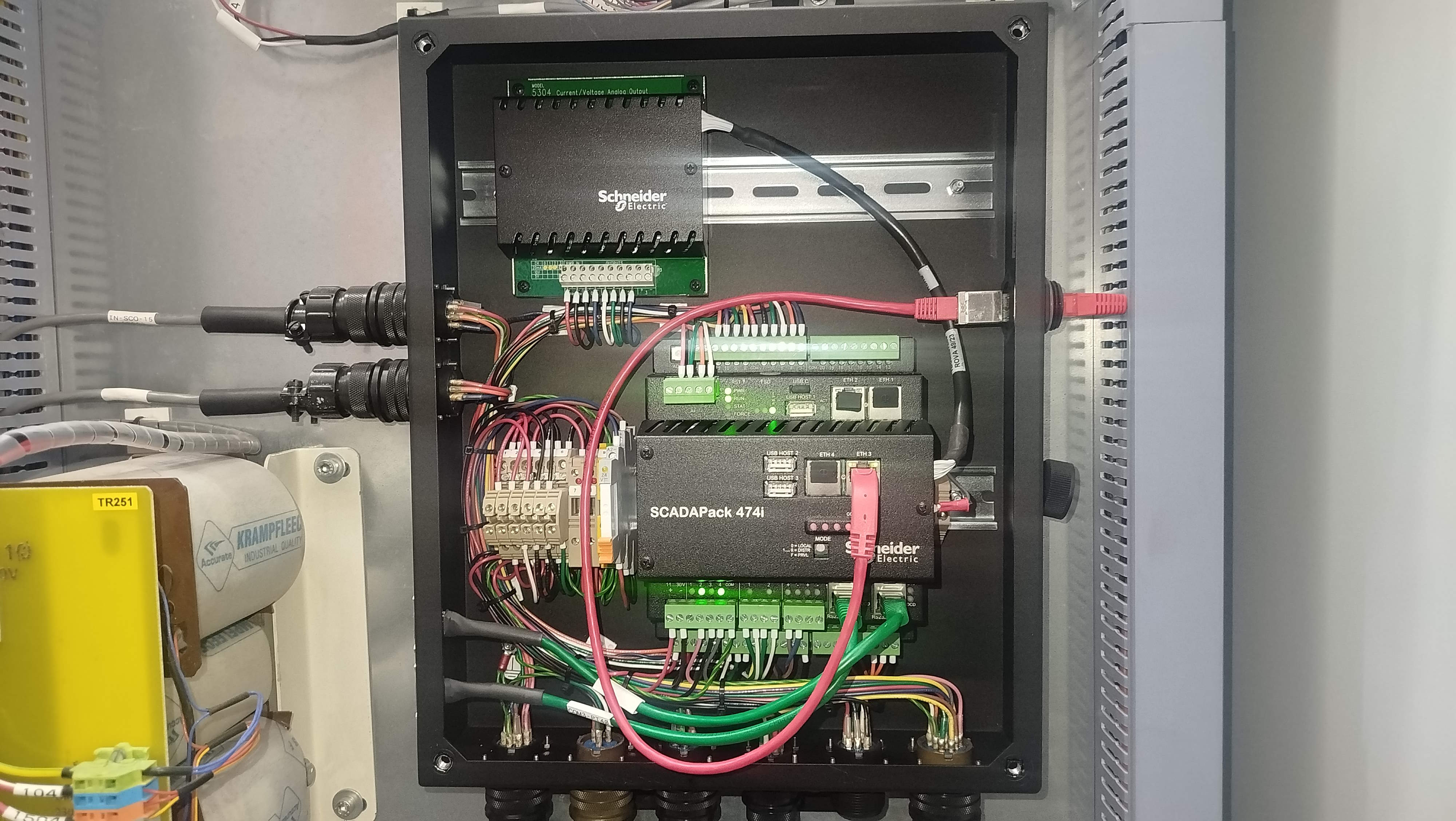

RTUs

Remote Telemetry Units or Remote Terminal Units are devices usually designed specifically to work with SCADA. They are rugged in construction, allowing them to operate well in harsh conditions. They are primarily used in processes where the machinery covers a long distance.

RTUs have no specific programming languages like PLCs, since they are used with a SCADA system. They have basic programming to enable them to understand data from input devices, accept control commands from the HMI, and issue commands to the output devices.

HMI

HMI - Human Machine Interface is the hardware component where the SCADA software is installed. The HMI can be a single computer for controlling a small industrial process or several computers (workstations, master stations) in a control room.

The HMI processes the data it receives from PLCs and RTUs. The SCADA software is the program the HMI uses for this data processing.

After data processing, the HMI displays the data graphically for operators to understand the conditions of the process, pointing out areas that need action and raising alarms.

The HMI provides a platform for the operator to issue commands; for example, a start or stop buttons on the HMI screen, enable the operator to send control commands to the process machinery.

Additional Hardware Components

OTI

OTIs - Operator Terminal Interfaces are small display screens located at specific pieces of machinery being controlled by the SCADA system. The OTI allows the operator to issue control signals locally, right at that machine, away from the main HMI.

OTIs are connected to the HMI through communication protocols, which we are going to discuss shortly.

Display Screens

These are screens installed in various areas of the process facility that display the graphical status of the machinery a SCADA system is controlling.

Sub-HMIs

These are computers located in remote control rooms, allowing an operator to control the machinery from a distance away from the main HMI.

SCADA Software

SCADA software programs and communication protocols are examples of software components of SCADA.

SCADA Software Programs

These are the software programs that the HMIs follow when processing the data from the PLCs or RTUs and then issuing control signals back to the PLCs and RTUs. The SCADA software programs are installed in the HMIs.

We have several SCADA software programs developed by different companies. The choice of SCADA software program depends entirely on your specific needs.

Communication Protocols

The communication between the RTUs or PLCs and the HMI is through communication protocols. Communication protocols are languages that system components use to communicate with each other.

For components to understand each other, they must use the same protocol. If the components use different protocols, they cannot communicate.

To enable communication between components with different protocols, an interpreter is needed. The interpreter used in a SCADA system is called a Gateway or Proxy.

We have several communication protocols, which are chosen based on the required speed, the amount of data transferred at once and the distance or coverage area. We have Fieldbus, Ethernet, and Wireless communication protocols.

Examples of Wireless include Wi-Fi, Bluetooth, Satellite, and Radio. Examples of Fieldbus include Modbus-RTU, Profibus, and CANbus. Examples of Ethernet include Profinet, EtherNet/IP, and Modbus-TCP.

Communication protocols are considered software components of SCADA because they define rules and formats for data exchange. The physical cables we see are just the medium for transimission of data.

SCADA Cyber Security

With machinery control being done remotely away from a central station, there is a possibility of someone injecting a virus that could harm the system and halt production

Virus or malware IS software developed by bad guys with a goal of destroying or disrupting others' work. Therefore, the SCADA system requires a serious focus on security.

Cybersecurity in SCADA systems is the practice of protecting these industrial control systems from unauthorized access, modification, or destruction.

If you have made it this far, you have made it. Consider visiting our YouTube channel; we have helpful electrical tutorials there.