How a Star-Delta Forward and Reverse Starter Works

A Star-delta forward and reverse starter is a starter widely used in industrial sites. As an electrician, it is important to understand how the starter works.

The star-delta forward and reverse starter has two circuits: the power circuit and control circuit. The starter enables the electric motor to run either in the forward direction or in the reverse direction.

The star-delta forward and reverse starter is found on industrial machines that are supposed to change direction of operation regularly.

A good example of the application of the star-delta forward and reverse starter is running a conveyor belt that moves objects from one place to the other.

The forward and reverse starter enables the conveyor belt to change the direction of rotation without reconnecting the phases to the electric motor.

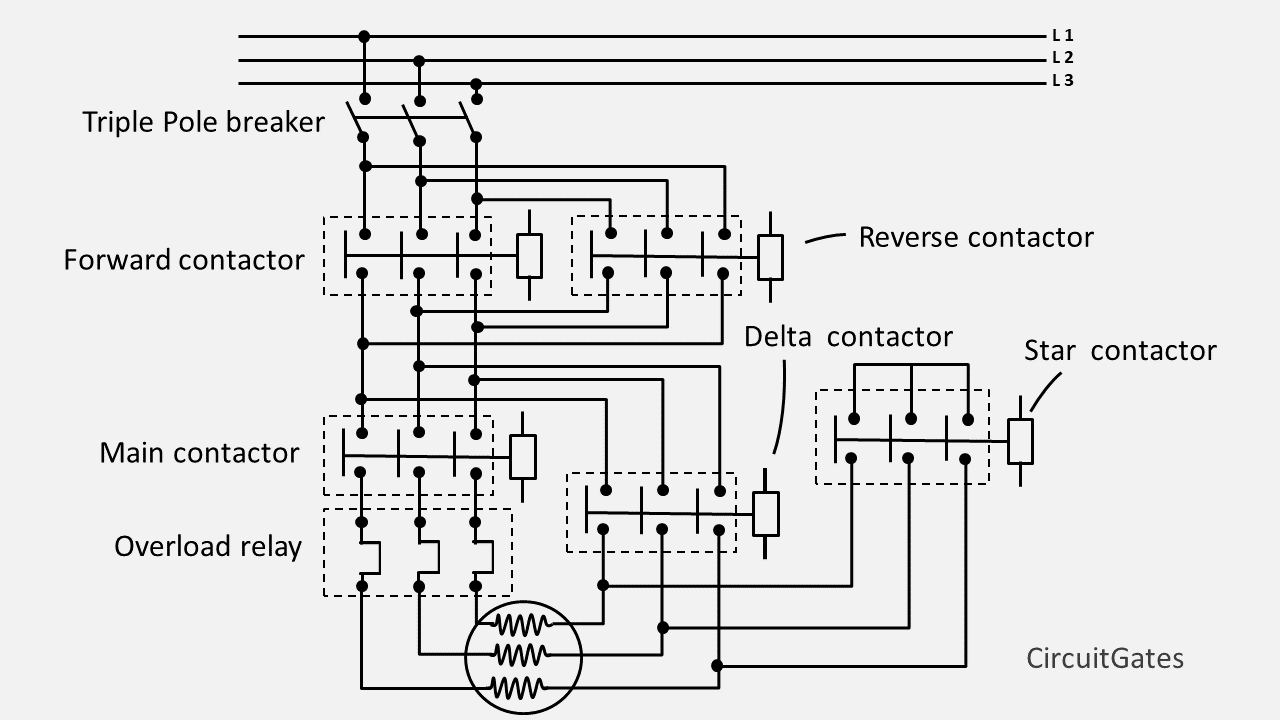

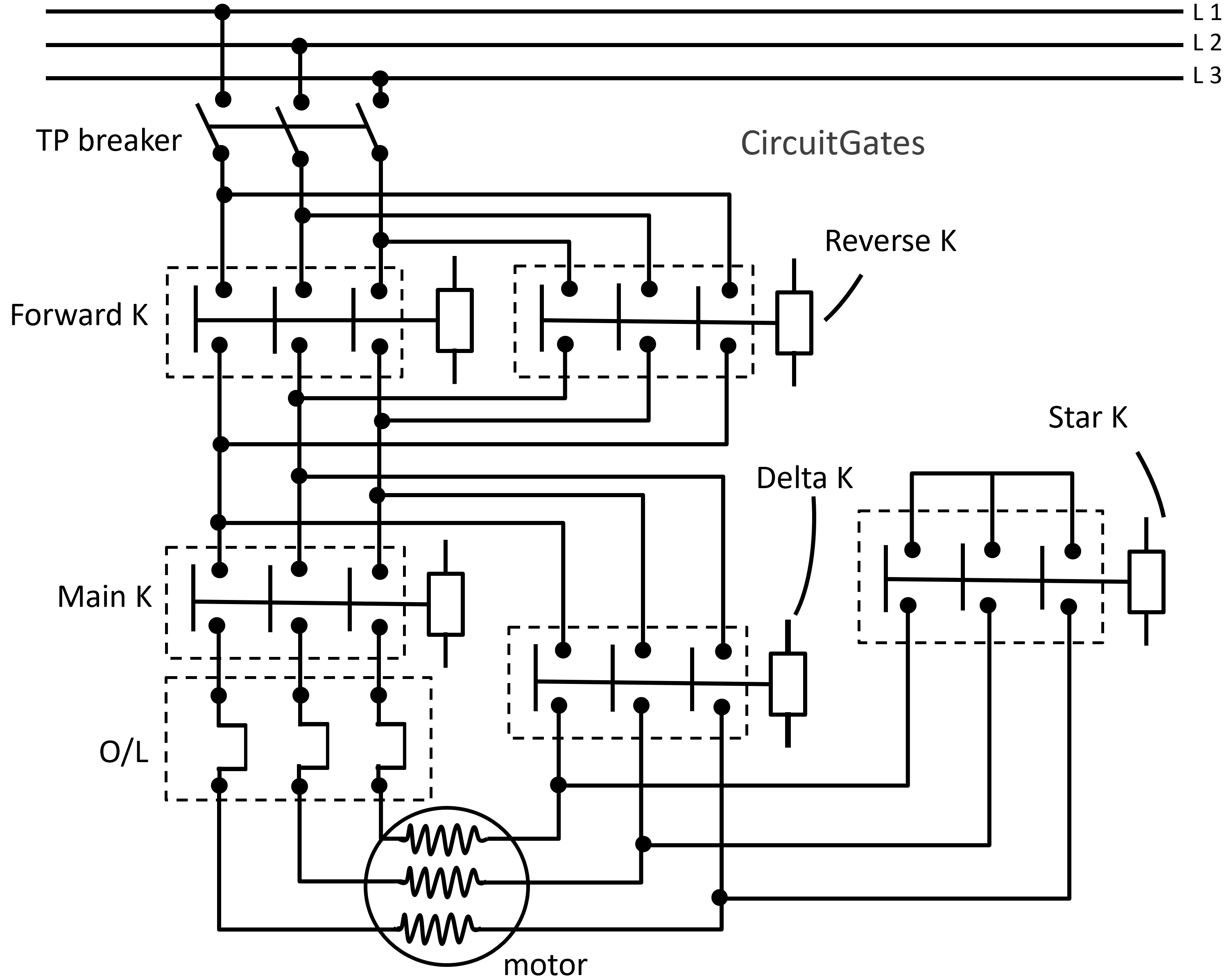

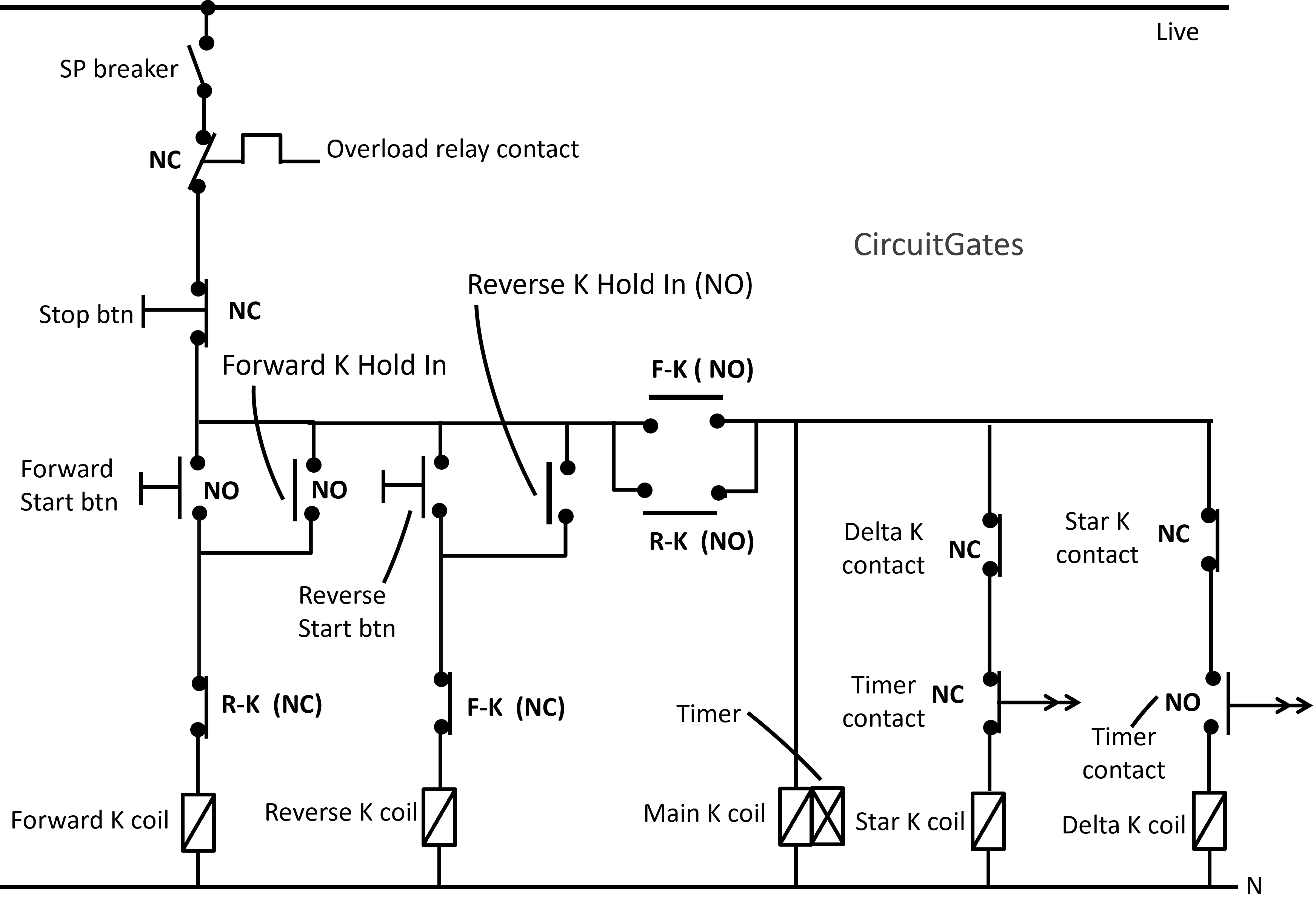

The diagrams below show the star-delta starter forward and reverse power and control circuits.

Power Circuit

Control Circuit

- TP Breaker - Tripple pole breaker

- SP Breaker - Single pole breaker

- K - Contactor

- btn - Button

- NC - Normally closed

- N - Neutral

- O/L - Overload relay

- NO - Normally open

- F-K - Forward contactor

- R-K - Reverse contactor

Key

Components of a Star-Delta Forward and Reverse Starter

As in the Previous Diagrams, the Starter Consists of:

1. Start Buttons (Forward and Reverse)- Start buttons are normally open contact buttons that are pressed to run the electric motor.

2. Stop Button - A stop button is a normally closed contact button that is pressed to stop the electric motor.

3. Circuit Breakers - Circuit breakers are devices that are manually operated to switch off the circuit for maintenance or they automatically trip, breaking the circuit in the event of a fault.

4. Overload Relay - An overload relay breaks or switches off the circuit in the event of an overload that causes overheating of the electric motor windings.

Overload is a condition in which current flowing in a circuit exceeds the amount required, leading to overheating of the electric motor windings.

Overheating of electric motor windings results in burning of the electric motor. Overloads usually do not cause tripping of circuit breakers, therefore there is a need for an overload relay.

5. Contactors (Forward, Reverse, Main, Delta and Star) - Contactors are devices that when current flows through their coils, close the contacts of the power circuit for power to reach the electric motor and vice versa.

6. Timer - A timer is a device that enables the electric motor to switch from star to delta.

7. Electric Motor - An electric motor is a device that converts electrical energy into mechanical energy.

How a Star-Delta Forward and Reverse Starter Works

On a star-delta forward and reverse starter, to start the electric motor in forward, the forward start button is pressed. When the forward start button is pressed, current flows through the forward contactor coil.

As current flows through the forward contactor coil, the coil becomes energized.

The energized coil pulls the power contacts and other normally open contacts of the forward contactor to the closed position, including the normal open contact labeled "F-K(NO)", and normally closed contacts of the forward contactor to the open position.

The contact labeled "F-K(NO)" allows current to reach the star-delta part of the control circuit.

As current flows through the main contactor and star contactor coils, their coils pull the power contacts and normally open contacts to the closed position and normally closed contacts to open position.

This results in power reaching the electric motor in star and the electric motor begins to run in forward direction.

After a preset timer time has reached, the timer opens the control circuit contact connecting the star contactor coil and closes the control circuit contact connecting the delta contactor coil.

This stops current from flowing through the star contactor coil while allowing current to flow through the delta contactor coil.

When current stops flowing through the star contactor coil and starts flowing through the delta contactor coil, the star contactor coil is de-energized while the delta contactor coil is energized.

This causes the star contactor power and other contacts in the closed position to open and vice versa for the delta contactor and the electric motor begins to run in delta in the forward direction.

We have already covered how a star-delta starter works; check out the explanations for further details.

To start the electric motor in reverse, we first need to stop the electric motor using the stop button, if it is still running in the forward direction and then press the reverse start button.

When the reverse start button is pressed, what happens is just the same as what we have said in forward direction except that the reverse components such as reverse start button and contactor are now in action.

When the reverse start button is pressed, current flows through the reverse contactor coil.

As current flows through the reverse contactor coil, the coil is energized and pulls the power contacts and other normally open contacts of the reverse contactor to the closed position, including the normally open contact labeled "R(NO)" and normally closed contacts of reverse contactor to open position.

The contact labeled "R-K(NO)" allows current to reach the star-delta part of the control circuit and the electric motor begins to run in reverse direction.

The contacts labeled R-K(NC) and F-K(NC) are for interlock, they prevent the electric motor from accidentally switching between forward and reverse directions.

The "Delta K contact" and "Star K contact" on the control circuit diagram prevent the electric motor from accidentally switching between star and delta configurations.